What is coverdrive?

coverdrive is a standalone controller designed to automate and simplify the tuning of magnetic loop antennas for amateur radio operation. It integrates directly with the radio, tracks frequency changes in real time, and precisely positions a vacuum variable or butterfly capacitor using a stepper motor. The system supports fully automatic SWR tracking as the operating frequency changes, while still giving the operator full manual control. When SWR calibration is performed, Coverdrive continuously seeks and maintains the lowest achievable SWR.

Overview

coverdrive is a complete control system for magnetic loop antennas, designed for amateur radio operators who want precise, repeatable tuning with both automatic and manual control.

The system combines a dedicated controller, stepper-driven capacitor control, live radio frequency tracking, and SWR feedback to deliver reliable loop tuning across multiple bands.

coverdrive is an experimental, builder-focused project developed in the spirit of amateur radio experimentation and learning.

What coverdrive Does:

coverdrive manages the relationship between your radio, loop antenna, and tuning capacitor by:

• Driving a stepper motor connected to a vacuum or air variable capacitor

• Tracking the radio’s live operating frequency

• Automatically positioning the capacitor for resonance

• Monitoring SWR using onboard ADC circuitry

• Allowing manual fine control when desired

The system supports both automatic tuning and hands-on adjustment, giving operators full control over how their loop behaves.

coverdrive Sidekick connects the controller to your radio using Omni-Rig v1.2, allowing the system to track the radio’s VFO frequency in real time.

coverdrive Firmware:

The firmware is the core of the system and is responsible for:

• Capacitor end-stop calibration

• Band setup and storage

• Stepper motor control

• Encoder and push-button handling

• Touch UI interaction

• SWR monitoring and refinement

• Alert and status messaging

System

coverdrive is a complete control system that combines dedicated hardware, embedded firmware, and companion software to manage the tuning of a magnetic loop antenna.

At the hardware level, an ESP32-based controller interfaces with a stepper motor driver, position sensing, and an analog measurement network used to monitor forward and reflected power. This allows the system to accurately position the tuning capacitor while observing antenna behavior in real time.

The firmware implements calibrated end stops for both the capacitor and individual bands, ensuring that all movement stays within safe mechanical and electrical limits. Once calibrated, coverdrive maintains a direct relationship between radio frequency and capacitor position, allowing repeatable tuning across bands.

During operation, frequency changes from the radio are tracked continuously. As the VFO is adjusted, the controller moves the capacitor to the expected resonance point and, when required, performs a refinement pass to locate the lowest achievable SWR.

User interaction is handled through a rotary encoder, push button, and a touch-based TFT display. The interface provides clear visibility of frequency, motor position, tuning direction, band limits, and system status, allowing both automatic and manual control at any time.

coverdrive is operated directly through its local interface.

To obtain live frequency data from the radio, a USB connection to a PC running the companion software “coverdrive SideKick” is required. The companion software interfaces with the radio using Omni-Rig, and forwards frequency information to coverdrive. Once this link is established, all tuning, calibration, and antenna control functions are performed by coverdrive.

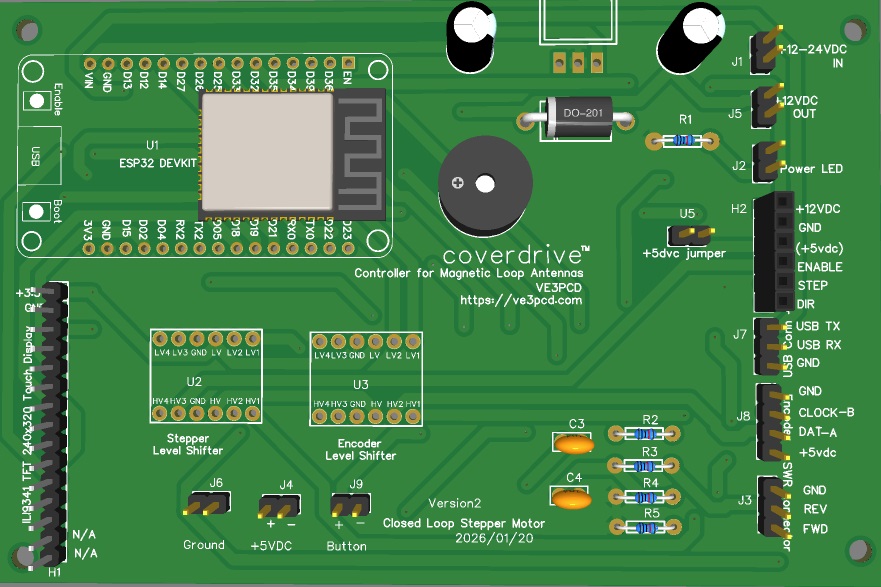

New Release

The new release of coverdrive represents the current and recommended hardware revision of the system. From a hardware perspective, the updated PCB adds native support for a USB connection to the radio interface and onboard audio feedback for system notifications and alerts. These additions simplify integration with modern station setups and improve operator awareness during calibration, tuning, and limit events. From a firmware perspective, the new release incorporates the full set of current features, including enhanced calibration workflows, band and capacitor end stop management, automatic refinement after frequency changes, improved stepper control, and expanded on-screen status reporting. The new release is intended for new builds and for operators who want full access to the latest functionality and ongoing firmware development. It is the reference platform for all current documentation and future updates. The system is provided as a PCB-only offering, allowing builders to select motors, drivers, and mechanical components that best match their antenna and operating requirements.

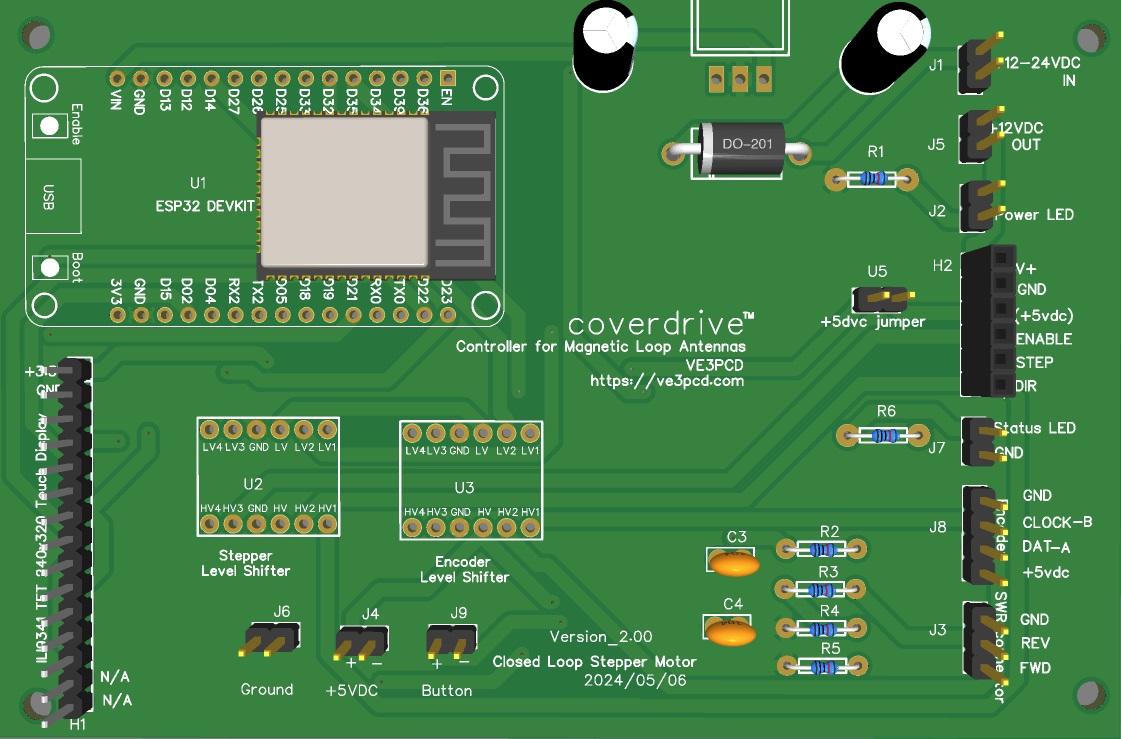

Lagacy

The legacy version of coverdrive refers to the earlier PCB revision that predates the current hardware release.

From a hardware standpoint, the legacy PCB does not include onboard support for the USB radio interface or the audio notification circuit. Builders who wish to use the current firmware features must manually add these functions by making a small number of direct connections to the ESP32. This includes wiring for the USB interface used to obtain radio frequency data and connections for the audio buzzer used for system alerts.

From a firmware perspective, the legacy hardware is compatible with the current coverdrive firmware once these connections are made. All operational features, including calibration, band management, tuning, and refinement, are supported when properly configured.

Legacy PCBs are offered in limited quantity and are intended for experienced builders who are comfortable with hardware modification, wiring, and troubleshooting. These boards are provided as-is and are not recommended for new builders.

This option exists to allow continued use of earlier hardware while transitioning toward the current coverdrive platform.

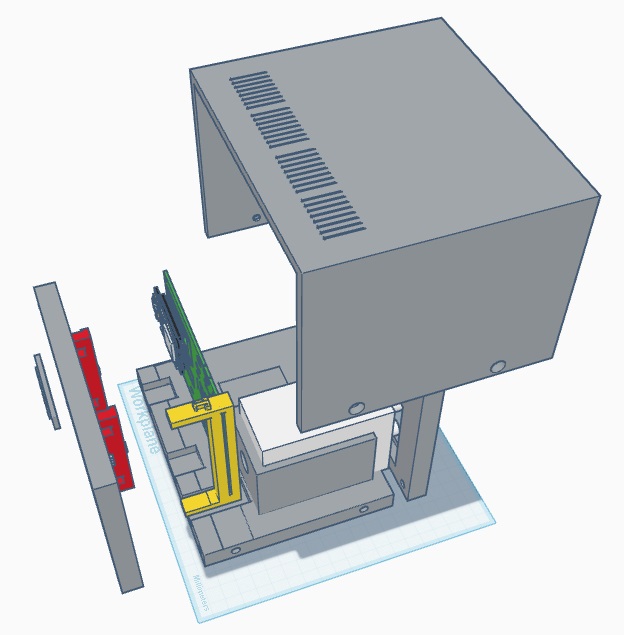

3D Enclosure

Enclosure Options

A purpose-designed enclosure is available for coverdrive, created specifically to support the controller hardware, display, encoder, and connectors in a compact and practical form factor.

The enclosure design consists of multiple interlocking 3D-printed components that provide proper alignment, ventilation, and access to all external connections. The layout is intended to support both bench use and permanent station installation.

Builders have two enclosure options:

STL Files:

The complete set of enclosure STL files is available for users who prefer to print and assemble the enclosure themselves. This option allows for customization of materials, colors, and printing parameters to suit individual preferences.

Assembled Enclosure Kit:

A complete enclosure kit is available for a small fee of $45.00 USD. The kit includes all required 3D-printed parts, ready for assembly, and is intended for builders who prefer a turnkey mechanical solution.

The enclosure option is independent of the controller PCB and allows builders to choose the approach that best fits their tools, experience, and build style.

Note: Enclosures are produced to order, with an estimated manufacturing time of up to 2 business days following receipt of payment, not including shipping.

Documentation

Documentation for coverdrive is organized by build and operating stages to make it easier to access the information you need at the right time. Documentation includes written manuals and short tutorial videos covering setup, calibration, and operation. Documentation Areas Getting Started System overview, operating concepts, and build planning. Hardware Setup & Calibration Capacitor setup, end stops, enclosure assembly, and initial calibration procedures. Band Setup & Operation Band configuration, tuning behavior, SWR tracking, and refinement operation. Legacy & Advanced Topics Legacy hardware notes, wiring modifications, and advanced configuration details. Documentation is provided on request to ensure compatibility with your specific hardware revision.

Product Availability & Options

coverdrive is offered in several formats to support different build styles, from experienced

builders to those looking for a quicker path to operation. All firmware, software, and documentation are provided free of charge.

New Release — Option 1

Bare PCB

• PCB – $20.00 USD

• coverdrive Firmware – Free

• coverdrive Sidekick Helper App – Free

• Related Documentation – Free

• Bill of Materials (BOM) – Free

• Schematic Diagram – Free

Best suited for builders who prefer to source and assemble all components independently.

New Release — Option 2

PCB + Pre-Flashed ESP32

• PCB – $20.00 USD

• ESP32 (firmware installed) – $25.00 USD

• coverdrive Sidekick Helper App – Free

• Related Documentation – Free

• Bill of Materials (BOM) – Free

• Schematic Diagram – Free

Ideal for builders who want to skip the firmware flashing step and get started faster.

Legacy Hardware (Limited Availability)

• PCB – $20.00 USD

• coverdrive Firmware – Free

• coverdrive Sidekick Helper App – Free

• Related Documentation – Free

• Bill of Materials (BOM) – Free

• Schematic Diagram – Free

Note: Legacy PCBs require minor hardware modifications to support the current firmware features.

Legacy Partial Kit (Limited Availability)

• Partial Kit – $150.00 USD

Includes:

• All components required to populate the legacy PCB

• ESP32

• TFT Touch Display

• Audio buzzer

• Push button

Not included:

• Wiring and cabling

• SWR bridge

• External connectors (stepper, DC power, USB)

• Rotary encoder

Also includes:

• coverdrive Firmware – Free

• coverdrive Sidekick Helper App – Free

• Related Documentation – Free

This option is intended for experienced builders familiar with system integration and wiring.

Enclosure Options

• 3D Printed Enclosure – $45.00 USD

• 3D STL Files – Free

STL files are provided for users who prefer to print their own enclosure or customize the design.

coverdrive is offered with the goal of making advanced magnetic loop control accessible to the amateur radio community. Pricing reflects hardware costs only; all software and documentation remain freely available.